Get Support

123-456-789-10

- Single system jacquard collar making machine

- 52 inch, (36-100inch all available )

- Single carriage with single system

- Collar, cuff, hat, carpet, scarf, sweater

- Maximum 1.6m/s

- Multi Language

- 1.5 KW, AC220v/380V, 50/60HZ

- Auto adjust

- Flat

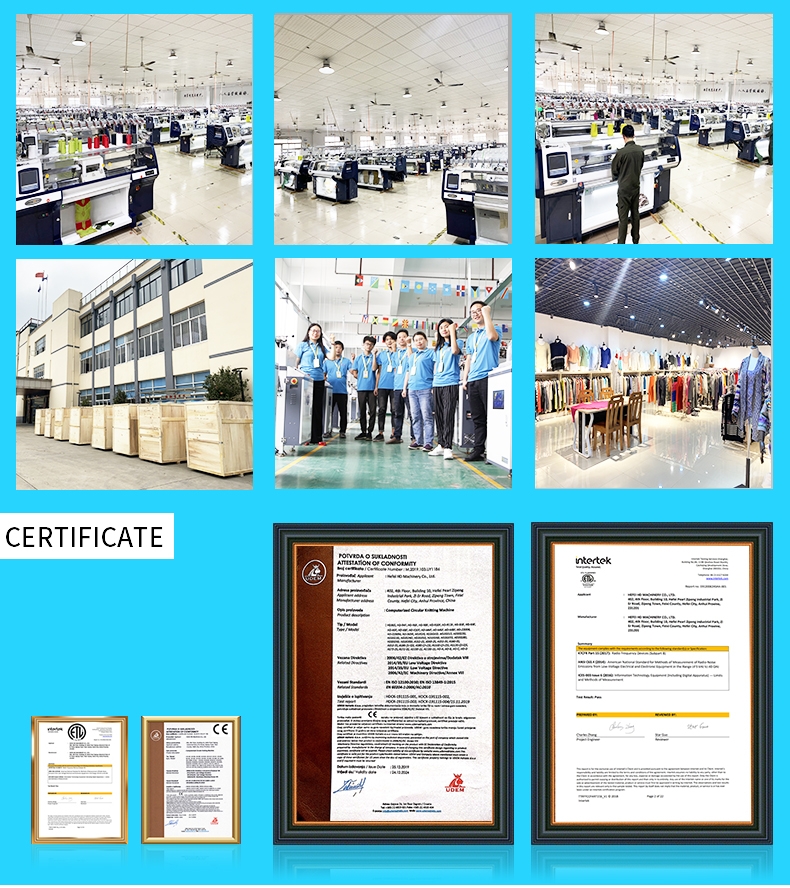

- ARROW STAR

Besides single system jacquard collar making machine, we can also supply three system sweater flat knitting machine, double system

sweater flat knitting machine, single system with double carriage collar & cuff knitting machine 80inch 1+1, double system

with double carriage sweater knitting machine 80inch 2+2 and three system shoes upper knitting machine etc.

Specification:

| Gauge |

12G, 14G, 16G |

| Knitting width |

52inch, (56inch, 60inch, 66inch, 68inch, 72inch, 80inch, 100inch, 120inch optioned) |

| Knitting function | Knitting single or double jersey, full needles, irregular jacquard, intarsia, cables, pointel fabric. |

| Knitting system |

Single carriage with single system |

| Knitting speed |

Max 1.6m/s |

| Stitch density | Stepper motor control, 24-segment density choices subdivision technology, adjustable range: 0-650degrees, more accurately control the length of the garment, using a dosed-loop system monitoring motor current location. |

| Dynamic stitch |

Various density changes and controls can be carried out in the same line. |

| Double Racking | Motor-driven. Max 1 inch racking each side (2 inches total). 1/2 and1/4 pitch also available from any position. |

| Takedown device |

Two monitor control roller, UP-POSITION roller |

| Transfer |

Simultaneous transfer, front or back, independent of carriage direction. Split stitch possible without exchanging yarn carriers. |

| Sinker system | The motor control sinker system, the new design of the sinker can play a better weaving function. |

| Needle selection |

Full jacquard selection via special solenoid actuators. 8 sections selection needles. |

| Takedown roller |

Prevention coiling device takedown roller, Electroplating ceramic roller, effective anti static. |

| Yam carriers | The new design of the color change device(lever principle), to eliminate the yarn feeder does not take. 2 sets of yarns are equipped with rollers to reduce yam breakage. |

| Top tension |

24units. One-touch easy threading. Large knots cause machine stop. Small knots cause 0-9 courses at specified knot detection speed, then automatically resume at set speed. |

| Stop motion | Yarn break, large knot, fabric pileup, shock detection, piece count, Over-torque, program error, etc. |

| Drive system | Belt drive. AC servo motor. No lubrication necessary. |

| Safety devices | Full safety cover for noise-suppression and dust-proofing with stop motion sensor and interlock mechanism. Emergency stop switch. Emergency power off device. Ultra-low speed "crawl" setting. |

| Needle detector |

Knitting area alarm, non alarm outside weave area. Automatic reset |

Single system jacquard collar making machine, single system with singe carriage series are used digital technology to achieve the patterns of transfer ,tuck ,pointel ,jacquard ,apparant shape ,hidden shape ,and other regular patter knitting functions. It is suitable for woven sweaters ,scarves ,hats and clothing accessories for silk ,synthetic yarn,wool,acrylic fibers ,blending yarn and other raw material .This model can adopt Raynen or Hengqiang software ,equipped with small carriage and fast rotation technology. Which greatly shortens the weaving time ,the efficiency of single side machine is 15% higher than previous type.

Dimensions of Single system jacquard collar making machine

| Package Size (L*W*H) | 2600*940*1800mm |

| Packing Material | Wooden Case |

| Net Weight | 500KGS |

| Gross Weight | 650KGS |